The integration of all enterprise aspects into a single system, achieved by an Enterprise Resource Planning (ERP) system, is deemed essential. This tool eliminates the need to worry about software maintenance and data consideration. This sector is known for its intricate operations, which include managing complex supply chains and maintaining exceptional quality standards. These challenges can be overcome with the use of Automotive ERP Software, a specialized tool designed specifically for the automotive sector. By enhancing efficiency and introducing innovation, this software becomes a valuable solution for tackling these obstacles effectively.

This blog post delves into the undeniable necessity of Automotive ERP Software, using compelling use cases and real-world examples to highlight its importance. We will explore the advantages that come with implementing customized automotive ERP software solutions. We will discuss the intricate process of ERP software development and shed light on the associated costs. By doing so, we aim to emphasize why investing in this transformative technology is an essential strategic decision for your automotive business.

What is an Automative ERP System?

An Automotive Enterprise Resource Planning (ERP) system refers to a specially designed software solution intended to address the distinctive requirements and difficulties encountered in the automotive sector. This system acts as a comprehensive and unified platform that automates and streamlines diverse business operations within automotive manufacturing and distribution enterprises.

An Automotive ERP System is primarily developed to enhance the synchronization of various operations, thereby improving efficiency, reducing costs, and increasing responsiveness. It comprises multiple features encompassing supply chain management, production planning, quality control, financial management, and customer relationship management.

Overview of Enterprise Resource Planning (ERP) for the Automotive Industry

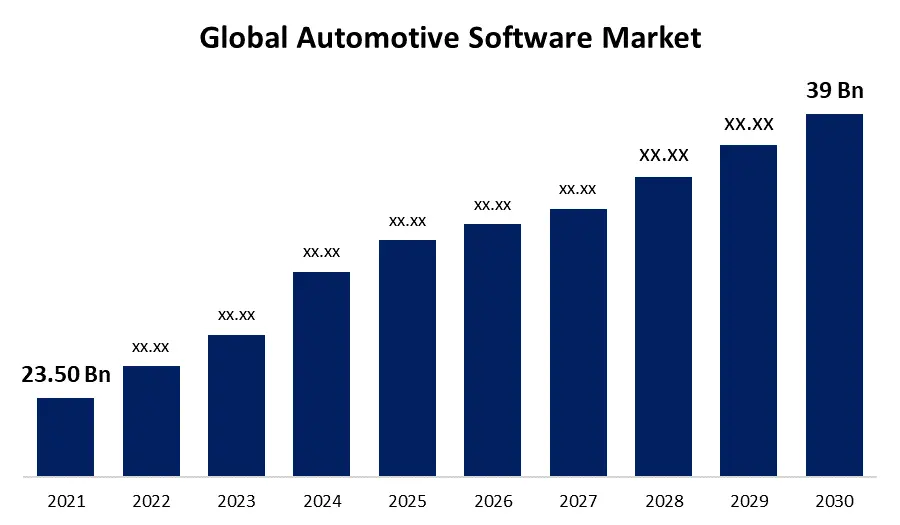

Based on data from Statista, the ERP software development market is predicted to reach around $101 billion by 2026. This growth is primarily attributed to the increasing demand for enterprise software across diverse industries. Within the automotive sector specifically, there will be a significant rise in the utilization of enterprise resource planning systems due to increased demand for both passenger cars and commercial vehicles. As more major industry players adopt ERP strategies, it is expected that the market will surpass projected growth boundaries.

As technology continues to advance, ERP software solution is expected to see further improvements in performance. These advancements, coupled with innovative strategies, are making ERP platforms more widely used in various downstream applications. One key advantage of ERP systems is their ability to provide real-time data insights, empowering businesses to make informed and data-driven decisions.

The Significance of ERP in the Automotive Sector

Enterprise Resource Planning (ERP) systems are crucial for guaranteeing efficient company operations in the automobile industry. Its key purpose centers on integrating and enhancing essential aspects of automotive manufacturing and management.

An automotive ERP system functions as a cohesive entity, seamlessly assimilating data from various departments such as production, supply chain, finance, and others. This centralized data repository eliminates isolated data environments, fostering transparency and facilitating collaboration across different functions.

An important aspect of its functionality is in the management of inventory, where ERP software development services systematically monitor stock levels. This ensures that the correct components are available at the appropriate location and time, thereby preventing the occurrence of excess stock and stockouts. Operational costs are reduced.

Automotive ERP software goes beyond the factory floor to efficiently handle HR and payroll tasks, streamline financial management, and ensure compliance with regulations. It equips businesses with robust analytics and reporting tools, strengthening customer relationship management initiatives.

Top 10 Automotive ERP Software Use Cases

Covering a range of applications, including supply chain management and inventory control, below outlines the key utilization scenarios of custom ERP software within the automotive industry.

1. Supply Chain Visibility: A Key Benefit of ERP Systems in the Automotive Industry

In the complex and dynamic realm of automotive manufacturing, having visibility into the supply chain is an absolute game-changer. It is the essential element that guarantees efficient and uninterrupted movement of components and materials from suppliers to the assembly line, ultimately determining the punctual delivery of finished automotive products to customers. Enterprise Resource Planning (ERP) systems become indispensable aids, providing real-time supply chain visibility that transforms the operational landscape of automotive enterprises.

Real-Time Insight into the Automotive Supply Chain through ERP Systems

In the automotive industry, Enterprise Resource Planning (ERP) systems serve as a valuable tool, offering a transparent perspective into the intricate network of supply chain operations. By gathering, centralizing, and presenting crucial information, these systems enable businesses to effectively trace and oversee the timely delivery of essential parts and components from manufacturers to assembly lines. The real-time visibility provided by ERP software development plays an indispensable role by equipping decision-makers with immediate access to the data required for making well-informed choices at a swift pace.

Improving Logistics Operations through ERP Systems

ERP systems also present a vital contribution towards advancing logistics operations within the automotive sector. By offering valuable information on transportation schedules, routes, and efficiency, these systems empower businesses to optimize their logistics processes, resulting in reduced transit times, fuel consumption, and overall transportation expenses. Hire software developers to get enhanced efficiency in logistics not only amplifies profitability but also fosters environmental sustainability.

Efficiency and Seamlessness in Manufacturing

Supply chain visibility has a profound impact on manufacturing operations, fostering a seamless production process. With up-to-the-minute insights into component and material availability, automotive manufacturers can optimize their assembly lines for smooth and efficient operations. By receiving components precisely when required, idle time and production downtime are minimized. As a direct outcome, ERP software cost savings are achieved, and production targets are met consistently, thereby ensuring a profitable and reliable manufacturing ecosystem.

2. Quality Assurance: Enhancing Automotive Product Quality through ERP Systems

In the intensely competitive automotive sector, guaranteeing superior product quality is not merely a priority but an absolute necessity. A crucial element in accomplishing this objective involves seamlessly integrating quality assurance procedures into the production cycle. In this regard, custom automotive ERP software solutions emerge as indispensable assets, providing strong assistance in the maintenance and improvement of automotive product quality.

Prompt Corrective Measures

The significance of identifying flaws at an early stage of production cannot be stressed enough. Take, for instance, the vital brake system component in automobiles. Tailored automotive ERP software can be customized to effectively monitor and evaluate the performance and quality of brake components. In the event of any irregularities or defects, the system promptly generates automatic alerts, initiating quick corrective actions.

3. Enhancing Efficiency and Profitability through ERP Systems in Production Planning

Effective production planning serves as a fundamental pillar of triumph in the realm of automotive manufacturing. In this intricate symphony of manufacturing, Enterprise Resource Planning (ERP) systems assume a crucial role, revolutionizing the automotive production process.

Resource Allocation and Optimization

ERP software plays the role of a conductor for the production process, effectively allocating every resource, be it manpower or machinery, in an optimal manner. By offering a real-time perspective on resource availability and needs, ERP systems empower automotive manufacturers to make informed decisions based on data.

Efficient Work Order Tracking with Streamlined Processes

Work orders epitomize the essence of production, and ERP systems demonstrate remarkable proficiency in their management. By leveraging ERP, automotive manufacturers can effectively generate, monitor, and oversee work orders throughout the entire lifecycle. In the event of an unforeseen issue, ERP systems offer the flexibility to promptly modify work orders, reallocate resources, or adjust schedules seamlessly.

Ensuring Profitability and Productivity Enhancement

The ramifications of proficient production planning enabled by ERP systems are extensive. Automotive manufacturers can significantly enhance their profitability by minimizing downtime, reducing the utilization of idle resources, and achieving a balanced production approach. By fully harnessing resources and optimizing production lines, the cost per unit decreases, resulting in a notable surge in overall productivity.

4. Enhancing Automotive Inventory Control through Tailored ERP Software

In the automotive sector, efficient management of inventory plays a vital role, as both manufacturers and dealerships must handle various parts and components seamlessly. To address this challenge, the advent of customized automotive ERP software has emerged as an influential ally, significantly transforming inventory management practices.

Preventing Resource Shortage

Custom automotive ERP software solution plays a crucial role in proactively addressing resource shortages through their ability to offer real-time inventory visibility. By keeping track of critical components and parts, manufacturers ensure they maintain optimal stocks at all times. This proactive approach significantly reduces the chances of production delays caused by missing parts, thereby ensuring a seamless manufacturing process.

Minimizing Carrying Costs

Carrying costs, encompassing warehousing and storage expenditures can exert a notable influence on a company’s profitability. Automotive ERP systems possess the proficiency to optimize inventory levels, guaranteeing a harmonious synchronization between stock quantities, production requirements, and market demands.

5. Financial Management: Enhancing Automotive Companies through ERP Software

Achieving success in the automotive industry heavily relies on efficiently managing financial processes, emphasizing the vital role played by Enterprise Resource Planning (ERP) software. ERP systems serve as the cornerstone for automakers, ensuring simplified and streamlined financial administration through the seamless integration of essential functions such as accounting, planning, and reporting.

Custom automotive ERP software solution offers automotive companies a comprehensive view of their financial landscape, enabling informed and strategic decision-making. This increased understanding of financial matters not only helps achieve short-term financial stability but also establishes the groundwork for sustainable long-term progress.

6. Customer Relationship Management

Integrating ERP systems with Customer Relationship Management (CRM) in the automotive industry offers a significant advantage. While ERP systems primarily improve internal operations, their collaboration with CRM systems greatly enhances customer service.

Improving Online Visibility

Integrating ERP with CRM systems enables automotive businesses to enhance their online presence effectively. Such systems facilitate the development of successful marketing initiatives, allowing businesses to connect with potential customers through a range of digital channels like websites, social media platforms, and email marketing.

Enhancing Sales Conversion

Streamlining leads to sales is made possible with the incorporation of CRM systems in the ERP framework. These systems empower businesses with lead management tools, enabling tracking of potential customers, meaningful interactions, and fostering relationships until the point of purchase.

Efficient Customer Relationship Management

The integration of ERP and CRM guarantees smooth management of customer relationships. By seamlessly capturing and storing customer data, interactions, and preferences, personalized engagement and customized services are facilitated.

Personalized Recommendations

An exemplary demonstration of ERP’s significance in customer relationship management lies in its capacity to assess customer preferences and offer tailored suggestions. Through data analysis, ERP systems can recommend products or services aligned with the customer’s interests, ultimately boosting the chances of repeat patronage and brand loyalty.

AI in CRM: Elevating CRM Performance to the Next Level

7. Regulatory Compliance: Maintaining Automotive Industry Standards through ERP Software

In the heavily regulated automotive industry, strict adherence to rules and regulations is not just a choice but a necessary requirement. These regulations span various areas, such as emissions standards, safety guidelines, and environmental norms. Their primary objective is to ensure that vehicles meet stringent criteria for both environmental safety and consumer protection.

ERP software solution acts as a powerful partner in addressing regulatory compliance in the automotive industry. It offers a strong foundation for companies to effectively monitor, comprehend, and comply with complex regulations. By consolidating data and streamlining processes, ERP systems greatly assist in monitoring changes and updates in regulations, guaranteeing that automotive businesses consistently operate within legal boundaries.

8. Data Analytics is Transforming Decision-Making in the Automotive Industry

In the modern scenario of the automotive industry, data has emerged as a valuable resource. The utilization of ERP (Enterprise Resource Planning) systems has provided automotive manufacturers with a significant advantage.

Resource Allocation Optimization

Through leveraging the capabilities of data analytics, ERP systems empower automotive manufacturers to achieve optimal resource allocation. These systems grant valuable insights into the utilization patterns of manpower, materials, and machinery, enabling precise allocation and the elimination of wasteful practices.

Operational Streamlining

Backed by ERP-driven data analytics, automotive companies can streamline their operations with unparalleled precision. Real-time data and performance metrics facilitate efficient identification and resolution of problems, leading to reduced downtime and enhanced overall operational output.

Making Strategic Decisions

ERP systems’ capacity to streamline strategic decision-making is a fundamental benefit. Through proficient data analysis, automotive manufacturers are empowered to make informed choices that directly impact company growth and profitability. For instance, a comprehensive examination of sales data can lead automakers to adjust production levels or refine marketing strategies based on evolving consumer expectations.

9. Enhancing Customer Satisfaction and Fostering Brand Loyalty in the Automotive Industry through Efficient Warranty Management

In the automotive industry, providing effective warranty and service management is vital for ensuring customer satisfaction and building brand loyalty. By implementing comprehensive systems, customers are empowered to easily handle warranty claims, schedule necessary maintenance, and coordinate vehicle repairs seamlessly whenever issues arise.

For example, when a car manufacturer offers a 3-year warranty, their ability to efficiently handle warranty concerns becomes incredibly important. This level of dedication not only shows their commitment to customer satisfaction but also serves as a proactive measure against costly recalls, ensuring the company’s reputation remains intact and fostering loyalty among customers.

10. Asset Management in the Automotive Industry: Enhancing Efficiency and Cost Reduction

Successfully navigating the dynamic automotive industry requires effective asset management. This involves overseeing and optimizing the lifespan of tangible assets like machinery, vehicles, and tools. By implementing efficient asset management strategies, organizations can properly allocate, maintain, and, if necessary, dispose of assets. This leads to cost reduction and improved production efficiency. In a car manufacturing facility, implementing an ERP (Enterprise resource planning) system is essential for maintaining and monitoring assembly line machinery. This ensures smooth and efficient operations while minimizing costly downtime.

How Much Does it Cost to Create a SaaS Platform?

Conclusion

In the highly competitive automotive industry, Automotive ERP Software is not just a luxury but an essential requirement. It plays a crucial role in streamlining operations and driving profitability by effectively managing supply chains, optimizing production, ensuring quality control, and enhancing customer relationships.

Customized automotive ERP software solutions offer a tailored approach, empowering businesses to adapt and excel in a dynamic marketplace. While there are costs involved in ERP software development, the long-term benefits and competitive advantages it brings make it a prudent investment for any automotive business aiming to thrive in the modern era. It is highly recommended to explore ERP software development companies, engage software developers, and fully embrace the transformative power of ERP technology. The future success of your business may significantly rely on it.

FAQs

What is Automative ERP Software?

Automotive ERP software serves as a valuable solution for automotive manufacturers to enhance their business operations. This software enables efficient management of various automotive processes and entails features such as inventory management, supply chain management, production planning, and financial management. By facilitating increased productivity, reduced expenses, and adherence to industry standards, automotive ERP software significantly optimizes the overall functioning of automotive companies.

What is the price range for customized automotive ERP software?

Several factors, such as the extent of customization, complexity, and specific demands of the automotive sector, collectively determine the cost of developing automotive ERP software. Costs for significant automotive businesses may vary from $150,000 to $750,000. It is essential to conduct a comprehensive evaluation and seek consultation from the top ERP software provider specializing in the automotive industry to obtain accurate cost estimates.